Are you a medical device manufacturer wondering how custom-made devices (CMDs) are regulated in the EU? Under Medical Devices Regulation (MDR) 2017/745, CMDs must comply with strict requirements to ensure safety and performance. This guide provides a clear breakdown of CMD compliance steps, key documentation requirements, and common challenges faced by manufacturers.

The medical device industry is one of the most regulated sectors, and bringing a CMD to market is a complex but rewarding process. Given the importance of safety and efficacy, CMDs are subject to strict regulatory oversight under EU MDR 2017/745.

For a broader understanding of medical device development stages, read this guide on the main phases of medical device development.

What is a Custom-Made Device (CMD) Under EU MDR?

According to Article 2(3) of the MDR, a CMD is a device that:

• Is manufactured based on a written prescription by an authorised healthcare professional.

• Has specific design characteristics tailored to a particular patient.

• Is intended solely for the use of that patient.

CMDs are not intended for large-scale distribution and are tailored to fit the unique anatomical or physiological requirements of an individual. CMDs are tailored to meet the unique needs of individual patients, which means they require a specialised approach to design, manufacturing and regulatory compliance.

Examples include:

• Patient-specific orthopaedic implants

• Tailored dental prosthetics

• Personalised hearing aids

For CMDs, device classification is still required. Manufacturers must provide a classification rationale and explain why the device qualifies as custom-made under MDR regulations.

How Do You Achieve MDR Compliance for Custom-Made Devices?

To ensure compliance with MDR 2017/745, CMD manufacturers must follow these seven key steps:

- What Are the Key Regulatory Requirements?

Compared to the previous Medical Devices Directive (MDD), the MDR introduces stricter requirements, including:

• Compliance with General Safety and Performance Requirements (GSPR) (Annex I). Manufacturers must demonstrate compliance with GSPR to ensure biocompatibility, safety and long-term performance.

• Mandatory risk management, clinical evaluation and post-market surveillance (PMS). - What Documentation Do You Need for MDR Compliance?

CMD manufacturers must maintain detailed documentation, including:

• Manufacturer’s Statement (Annex XIII) – Declaring MDR compliance

• General Safety and Performance Requirements (GSPR) (Annex I)

• Device Description – Covering design, manufacturing and intended use

• Risk Management File – Identifying hazards and mitigation strategies

• Clinical Evaluation – Providing safety and performance evidence - What Are the General Safety and Performance Requirements (GSPR) (Annex I)?

CMDs must meet MDR’s GSPR, ensuring:

• Biocompatibility – Materials are safe for human use

• Sterilisation Validation – If applicable

• Labelling & Instructions for Use (IFU) – Clear labelling and usage instructions for patients and healthcare professionals - Do You Need a Quality Management System (QMS)?

Yes. Manufacturers must implement a Quality Management System (QMS) aligned with Article 10(9) MDR and ISO 13485 (the only QMS standard harmonised under EU MDR). This ensures ongoing regulatory compliance and covers many topics, for example:

• Risk management procedures

• Manufacturing controls

• Traceability of materials - What Are the Post-Market Surveillance (PMS) Requirements?

The MDR emphasises post-market surveillance (PMS) to ensure ongoing device safety. Required reports include:

• Post-Market Surveillance Report (PMSR) for Class I devices (Article 85 MDR)

• Periodic Safety Update Report (PSUR) for Class IIa, IIb, and III devices (Article 86 MDR)

• Incident Reporting – Serious incidents and field safety corrective actions must be reported to authorities

CMD manufacturers must also comply with post-market clinical follow-up (PMCF) requirements to assess long-term safety and effectiveness. - When Is Notified Body Involvement Required?

In accordance with MDR Annex XIII, CMDs generally do not require Notified Body (NB) involvement, except for high-risk devices (e.g., Class III implantable CMDs), which require:

• Conformity assessment under Annex IX (MDR Chapter I) for class III CMDs

– The manufacturer may choose to apply a conformity assessment as specified in Part A of Annex XI of the MDR.

• Annex XIII Statement instead of a Declaration of Conformity (Section 1 of Annex VIII)

– This statement shall be made available to the particular patient or user identified by a name, an acronym or a numerical code. - Are There Any MDR Exemptions for CMDs?

Some exemptions apply:

• Unique Device Identification (UDI) exemption (Article 27 MDR) – Traceability records must still be maintained

• No CE marking required (Article 21(1)(b) MDR)

• No Summary of Safety and Clinical Performance (SSCP) required (Article 32(1) MDR)

Additionally, a Person Responsible for Regulatory Compliance (PRRC) must be appointed under Article 15 MDR but does not need to be registered in EUDAMED.

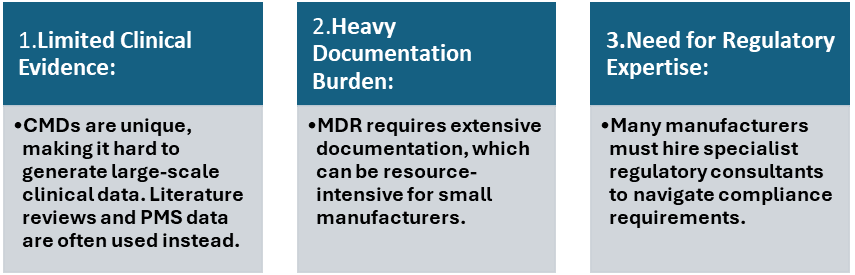

What Are the Common Challenges in MDR Compliance?

If you are considering working with a regulatory consultancy, read this guide on choosing between a consultant and a consultancy.

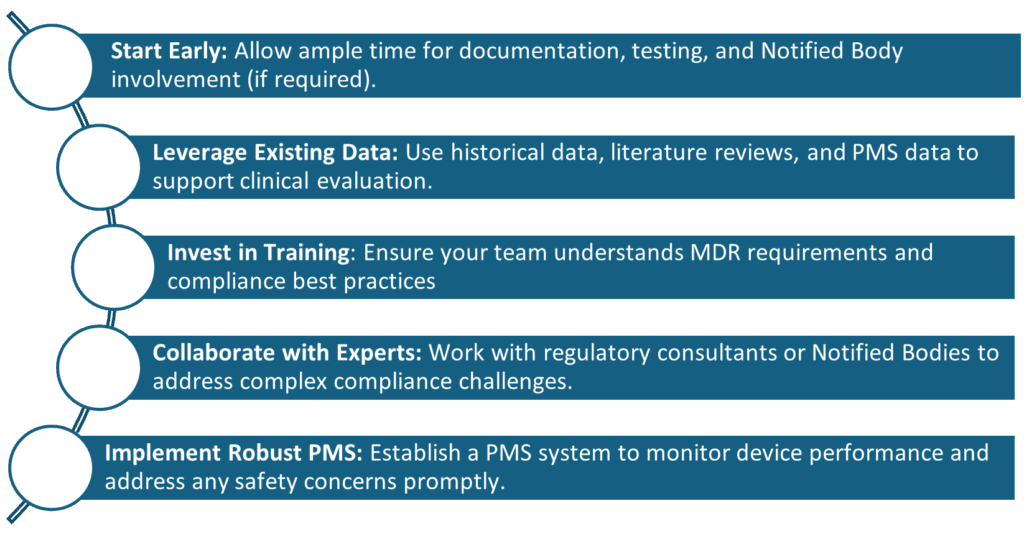

Tips to Ensure MDR Compliance for Custom-Made Devices

FAQs: Common Questions About CMDs and MDR Compliance

Q: Do custom-made devices need a CE mark?

A: No, CMDs are exempt from CE marking under Article 21(1)(b) MDR.

Q: Do CMDs require Unique Device Identification (UDI)?

A: No, but manufacturers must maintain traceability records (Article 27 MDR).

Q: Can CMDs be mass-produced?

A: No, CMDs must be patient-specific and prescribed by an authorised healthcare professional.

Q: Do all CMDs need Notified Body approval?

A: No, except for Class III implantable CMDs, which require assessment by a Notified Body.

For companies navigating the complexities of regulatory compliance, understanding the role of a UK Responsible Person is crucial. Learn more about UK Responsible Person requirements here.

Conclusion: How to Stay Compliant with MDR

The EU MDR 2017/745 imposes strict regulations on CMDs to ensure patient safety. To achieve compliance, manufacturers should:

✅ Understand MDR requirements

✅ Maintain thorough documentation

✅ Implement a robust QMS & PMS system

✅ Leverage expert guidance and available resources

By staying proactive and compliant, CMD manufacturers can not only meet MDR regulations but also enhance patient trust and device credibility in the market.

Need expert guidance on MDR compliance? Contact us today to ensure your custom-made devices meet EU regulations!

Yupei Xiao

Dr Yupei Xiao specialises in regulatory and clinical affairs for in-vitro diagnostics

(IVDs) and medical devices (MD), and she supports clients from startup stage to

market submission. With expertise in performance evaluation, clinical evaluation,

biological evaluation, and quality management systems, she helps companies

navigate complex regulatory landscapes, ensuring compliance with MDR, IVDR, and

ISO 13485:2016 standards.

With a Ph.D. in Respiratory Medicine and over a decade of experience in clinical

trials, medical affairs and regulatory affairs, Yupei has supported startups and

established firms in preparing technical files, conducting post-market surveillance,

and implementing ISO-certified Quality Management Systems, led performance and

clinical evaluations, supported international product registrations, and contributed to

peer-reviewed publications and global regulatory submissions. Her work spans

Medical devices, in-vitro diagnostics (IVDs) including the companion diagnostics,

and Software as a Medical Device (SaMD), with a focus on EU and UK markets.

Yupei combines deep technical knowledge with a practical approach to deliver

compliant, timely outcomes. Her unique perspective bridges clinical science and

regulatory strategy, making her a trusted advisor in the IVD and Medical Device

industry.