Navigating the intricacies of EU/UK medical device regulations in preparation for the creation of technical documentation that is necessary for market entry, can prove challenging; and it can also be incredibly difficult to understand the requirements to streamline the reviewal process.

As if the requirements aren’t complex enough, we need to be prepared for the increased scrutiny of devices due to changes from directive to regulation under EU MDR 2017/745 & IVDR 2017/746; and tolerate the uncertainty of the UK regulatory framework; so, it is not surprising you could be feeling somewhat confused by it all.

As regulatory experts, we commonly encounter recurrent problems where technical documentation does not comply with applicable regulatory requirements. This has the potential to cause delayed market access, which can impact on patient health and stifle new technology innovation.

In this blog we will look at some of the common problems we find when reviewing or remediating client technical files.

1. Defining a well-rounded intended use

Defining your intended purpose and indications for use of your device is a critical first step. This not only defines the classification of your device which stipulates the regulatory pathway but can also all subsequently define aspects of your clinical evaluation.

The IVDR clearly states the requirements for the intended use of an In Vitro Diagnostic, with section 1.1 of Annex II defining what information needs to be captured. The MDR also captures what information needs to be considered but not as the extensive as the IVDR.

The device description and intended use of your device can and will impact the classification of your device. Understanding these early in the development process of your product, will allow you to plan accordingly and make sure you go down the correct regulatory classification and pathway.

2. Is your technical file structure easy to follow?

Is your technical file presented in a clear, organised, readily searchable and unambiguous manner? Annex II & III under the MDR 2017/745 and IVDR 2017/746 both stipulate that the technical documentation should be organised and goes on to document what the content shall consist of with detailed information.

- Device description and specification, including variants and accessories

- Information to be supplied by the manufacturer

- Design and manufacturing information

- General safety and performance requirements (GSPR’s)

- Benefit-risk analysis and risk management

- Product verification and validation data

- Post market surveillance.

As a consultancy who work with many different companies, we regularly come across technical files which have not necessary been set out in the most logical manner. It is always best to get a second opinion as a layout that works for you, does not always work for everyone else, including the reviewer. Having a well-presented, descriptive technical file will aid with a quicker and more efficient audit review and reduce the number of unnecessary questions asked by your Notified Body.

3. Keeping your technical file up to date

You have created your technical file, so what’s next? Keeping your technical documentation up to date seems simple right? But it is a common issue we see and one that can be avoided, not only in the updating your technical documentation when you have made changes, but also making sure you keep the contents of your file updated e.g. systematic update to clinical evaluation, risk management file.

As a medical device manufacturer selling product on the EU/UK market, you need to maintain, and keep up to date, your technical file for each device and throughout its lifecycle. You can aid this by making sure you have a well-defined change control process in place that takes into consideration changes that could impact your technical documentation

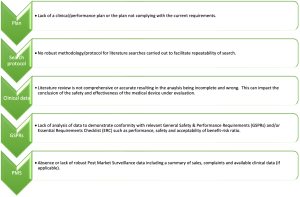

4. Clinical/performance evaluation documentation

We routinely come across clinical/performance evaluation documentation issues presented in the technical file. Whilst we have observed the following common issues, the list is not exhaustive:

To avoid these common mistakes, you should ensure that your clinical/performance evaluation documentation is prepared in accordance with the respective regulations and available guidance e.g. MDCGs, Meddevs. Your internal procedures should also reflect the regulatory requirements as well as current practice within your business to facilitate the creation of evaluation documentation.

5. Risk management activities

ISO 14971 is the standard used for the application of risk management to medical devices and has been around for many years. Regardless to its longevity, companies consistently struggle to be compliant with risk management requirements.

One common issue is remaining up to date with the latest standard for carrying out risk management activities. We find on occasions, that the latest 2019 version is not being followed and there are some instances where the 2012 version is still being followed. It should be noted that the transitional period for being able to claim compliance with the 2012 version has now passed and you will be classed as not following the state of art resulting in non-compliance.

We also find that risk management activities are carried out to a compliant level when populating during the design & development phase. Once the device has been transferred into production, the risk management file is not regularly reviewed or kept up to date. ISO 14971 clearly documents the requirements for the lifecycle process of any device marketed which includes production and post-production information.

It is worthwhile having a robust procedure in place with appropriate training (where applicable) to facilitate with the process and any additional activities that may be required.

6. Non-compliance with post market surveillance requirements

Finally, the issues with see with technical files is creating and updating post-market surveillance documentation. Regardless of the status of your medical device and how long it has been on the market, there are obligation requirements set out under Annex III of the MDR/IVDR that clearly defines manufacturer responsibilities.

Some of the main issues we have encountered are as follows:

- A failure to generate PMS plans that are compliant with the requirements of MDR/IVDR

- Not ensuring that Periodic Safety Update Reports (PSURs) are created in line with their reporting periods based on classification.

Final Thoughts

Some of the issue examples listed above are only a subset of many we see. Technical documentation is a living document that is not only required to meet regulatory requirements during development but is also kept up to date as and when needed after the launch of your device.

Need Help….

If you have any questions regarding technical file creation, gap analysis or remediation and/or consulting services please get in touch with our experts today by phone on +441484662575 or via info@lfhregulatory.co.uk. Alternatively, fill in your details below and we will contact you.